Detailed introduction

Introduction

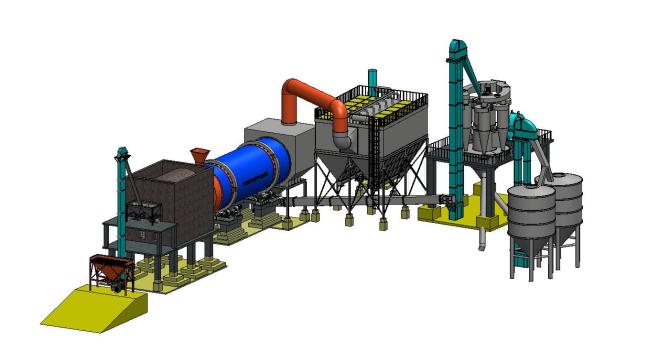

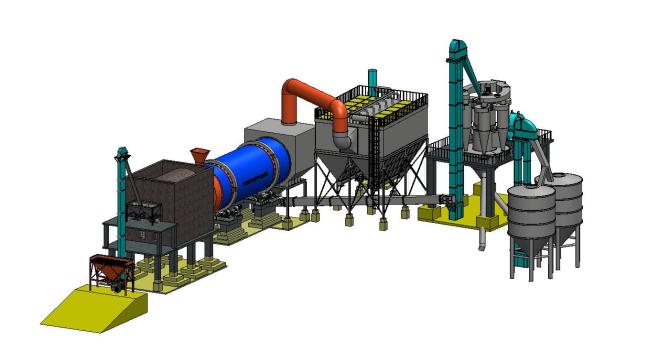

Fly Ash Drying System is custom-designed and manufactured to suit the customer’s individual project needs. These drying systems consist of a correctly sized drum with a burner. The burner is mounted to a combustion chamber. Fly Ash Drying Systems are designed specifically to dry fly ash, making the material easy to transport, store and handle.

Features

1. In the coal fired power plant, the fly ash has two discharging style: one is dry discharging style, the other is wet discharging style.

2. In the rapidly developing cement industry, as the cement production mixing materials, the dry fly ash market is rather considerable. The physicochemical properties of wet fly ash are basicly same as the dry fly ash, but as there is big moisture content (maximum is amount to 45%), the wet fly ash can not meet the requirements of cement production. As a result, the wet fly ash can only be piled up as waste, and occupy many storage place, even pollutes the environment.

3 Then, how to dry the wet fly ash ?

After years' research, Yuhong Machinery developed one new type fly ash dryer. It has the advantages of low energy consumption, simple drying process, large drying capacity, etc. Fly ash dryer from yuhong Machinery can dry the wet fly ash from moisture content 45% to about 8% in large quantity directly.

working principle

Fly ash is fed into the rotary dryer. After passing through the dryer, the dried material is discharged to a transfer conveyor for further sorting and separation. The vapor from the process is pulled through a cyclone that is specifically designed to deal with the fine dust, as well as a high-temperature baghouse which removes all fine particulates from the vapor stream.

Technical parameters

| Model | Ф2.0×6m | Ф2.5×6.5m | Ф3.2×7m | Ф3.6×8m | Ф4.2×8.5m |

|---|

| Drum volume (m3) | 18.84 | 31.89 | 56.26 | 81.38 | 118 |

|---|

| Rotating speed (rpm) | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 |

|---|

| Input moisture (%) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

|---|

| Output moisture (%) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

|---|

| Max. input temperature (℃) | 750-900℃

| 750-900℃ | 750-900℃ | 750-900℃ | 750-900℃ |

|---|

| Capacity (t/h)-Fly ash | 8-12 | 18-25 | 30-35 | 40-45 | 50-58 |

|---|

| Motor model | Yr160m-4 | Yr132m-4E | Yr132m-4E | Yr160m-4E | Yr160m-4E |

|---|

| Motor power (kw) | 5.5×2 | 7.5×2 | 7.5×4 | 11×4 | 15×4 |

|---|

| Speed reducer | XWD-6 | XWD-6 | XWD-6 | XWD-6 | XWD-6 |

|---|

| Speed ratio | 23-29 | 23-29 | 23-29 | 23-29 | 23-29 |

|---|

| Machine weight (t) | 25 | 32 | 40 | 56 | 76 |

|---|

Focus on Quality, Serve Worldwide

Establish strong sales service system with full coverage for 6 continents, 140 countries.

Whatever your requirements, you 'll find the perfect service-oriented solution to match your specific needs with our help.

Right where you need us,whenever you need us

ATTENTION! WE HAVE ONE-STOP SPARE-PARTS SUPPLY CHAINAll kinds of parts, Full range of models