Detailed introduction

450Overview

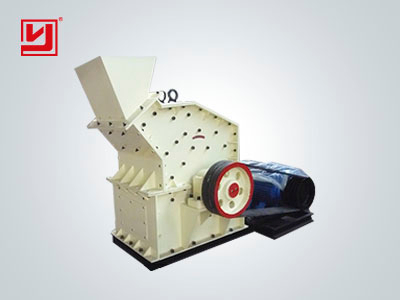

These series of impact fine sand maker are designed for crushing ores and rocks with particle size no more than 500mm and compression strength no more than 320MPa. They enjoy features of high crushing ratio, high-efficient crushing, cubic shape of product, alternative crushing, etc. and they are ideal aggregate processing widely used in expressway, hydropower construction, airport and building industries.

Features

1.Discharging granularity is adjustable.

2.Sieve plate adopts special spring concession structure, simple, convenient, reasonable, safe and stable.

3.Adopt elasticity constant force and make crushing force stable.

4.Adopt high alloy hammer head, it can reduce abrasion, extend lifespan, and has high efficiency.

5.Mixing pad can exchange, also can increase the lifespan. Do not block and it has high safty.

6.Compared with hammer crusher and impact crusher, it can only wear rotor, and can not wear wheel core and hammer carrier.

7.It is easy to maintain, we only need to hoist the upper box, and open the lower box.

8.Adopt multi-layer three channel discharging device, it can discharge the material at time, and improve the capacity.

9.Adopt solid rotor, rotational inertia, and strong hitting power.

Working Principle:

The impact fine sand maker works in continuous operation. Driven by the motor the rotor rotating quickly and to-be-broken materials are fed into the first chamber and crushed by hammer, then be fed into the crushing cavity II for further crushing, finally discharged port through discharging mouth.

Technical Parameter

|

Impact Fine Sand Maker

|

rotorФwidth(mm)

|

rotorФwidth(mm)

|

rotorФwidth(mm)

|

rotorФwidth(mm)

|

rotorФwidth(mm)

|

rotorФwidth(mm)

|

rotorФwidth(mm)

|

rotorФwidth(mm)

|

|

Model

|

PCX0804

|

PCX0806

|

PCX0808

|

PCX1010

|

PCX1212

|

PCX1414

|

PCX1616

|

PCX1818

|

|

Feed opening (mm)

|

400×185

|

500×250

|

550×300

|

1000×350

|

1200×450

|

1500×500

|

1600×550

|

1800×800

|

|

Max feeding size(mm)

|

<120

|

<180

|

<180

|

<180

|

<180

|

<190

|

<190

|

<190

|

|

Adjustable discharging opening (mm)

|

5-10

|

5-10

|

5-10

|

5-10

|

5-10

|

5-10

|

5-10

|

5-10

|

|

Adjustment width of the discharge gap(mm)

|

5-50

|

5-50

|

5-50

|

5-50

|

5-50

|

5-50

|

5-50

|

5-50

|

|

clinker(t/h)

|

10-30

|

18-40

|

20-45

|

25-55

|

50-110

|

50-150

|

85-210

|

125-270

|

|

limestone(t/h)

|

18-45

|

23-55

|

28-65

|

35-75

|

45-100

|

50-150

|

95-260

|

140-310

|

|

power(kw)

|

37

|

37

|

45

|

55

|

110

|

160

|

250

|

315

|

|

weight(t)

|

3.9

|

4.5

|

6

|

10.5

|

14.4

|

22

|

35

|

49.7

|

Focus on Quality, Serve Worldwide

Establish strong sales service system with full coverage for 6 continents, 140 countries.

Whatever your requirements, you 'll find the perfect service-oriented solution to match your specific needs with our help.

Right where you need us,whenever you need us

ATTENTION! WE HAVE ONE-STOP SPARE-PARTS SUPPLY CHAINAll kinds of parts, Full range of models