Detailed introduction

Processed Materials: Iron ore, lead and zinc ore, silver and manganese ore, molybdenum and rhenium ore, other metallic ores and non-metallic ores.

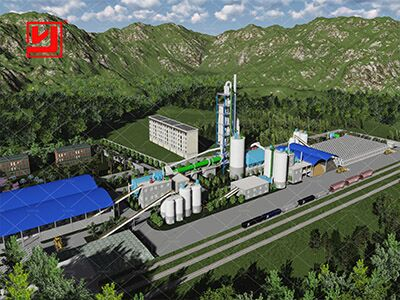

Applications: Cement plant, metallurgy industry, chemical industry, building refractory materials, environmental protection, etc.

Introduction:

Rotary kiln is the key equipment for the calcination of bauxite, clinker, limestone, etc.. According to the capacity of bauxite plant, clinker or cement plant, etc., we can help you select different size of rotary kiln, which is usually from 900mm to 4000mm.

Rotary kiln is mainly composed of kiln shell, refractory bricks, supporting device, supporting device with catch wheel, transmission device, lubrication device, mobile kiln head and sealing device at the end of the kiln.

1. Supporting device: advanced shaft structure, automatic temperature measuring device and electrical heating.

2. Catch wheel: including two kinds mechanical wheel and hydraulic pressure.

3. Gears: single or double. Control the rotating speed by buncher, DE machine and frequency variable motor. Be reliable, energy-saving, and efficient.

4. Kiln shell tire bolster: lower bolster has three types: fixed, zoom and floating. The structure is simple, replacement is convenient and won’t hurt cylinder.

5. Sealing equipment: there are many kinds for choice according to kiln models, including air cylinder edge sealing, spring edge sealing, and graphite block sealing and combination for above. The sealing effect is very good.

6. Kiln head hood: including stationary type and flexible type.

Working Principle:

Material will be feed into kiln tail through chute in gas chamber. As kiln shell is inclined and it rotates slightly, material will move along round shell and will also move along shaft direction from kiln tail to kiln head. Material will be processed through pre-heat, decompose, calcined and will be feed into cooler. Fuel will be given through gas or coal burner at kiln head and will be combusted in kiln. Heat will be transferred to material by fire radiate, hot air flow, kiln brick transfer. The heat will heat and calcine material enough and make it final product.

Advantages:

1. Through technological innovation, our rotary kiln is designed with international leading wheel catch device, high precision plunger metering pump, high accuracy speed control valve and contact graphite block sealing device, etc.

2. In order to improve machinery automation, an industrial computer is used for showing the calcining condition, and a fluorescent screen is adopted for showing the simulated process flows. An infrared scanner is utilized for transmitting the calcining condition to the computer.

3. These new technologies provide our rotary kiln with strong visual sense, convenient operation and reliable performance. They help stabilize thermal regulation and improve operation efficiency.

4. Comparing with other similar cement production equipment, the operation rate of our rotary kiln increased by 10%, production increased by 5%-10% and heat consumption decreased by 15%.

Technical Parameters

| Model | Kiln dimensions | Output | Rotation Speed | Power | Weight |

|---|

| Diameters | Length | Gradient |

|---|

| (mm) | (mm) | (%) | (t/h) | (r/min) | (kw) | (t) |

|---|

| φ1400×33000 | 1.4 | 33 | 3 | 0.9-1.3 | 0.39-3.96 | 18.5 | 47.5 |

| φ1600×36000 | 1.6 | 36 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 52 |

| φ1800×45000 | 1.8 | 45 | 4 | 1.9-2.4 | 0.16-1.62 | 30 | 78.2 |

| φ1900×39000 | 1.9 | 39 | 4 | 1.65-3 | 0.29-2.93 | 30 | 77.59 |

| φ2000×40000 | 2 | 40 | 3 | 2.5-4 | 0.23-2.26 | 37 | 119.1 |

| φ2200×45000 | 2.2 | 45 | 93.5 | 3.4-5.4 | 0.21-2.44 | 45 | 128.3 |

| φ2500×40000 | 2.5 | 40 | 3.5 | 9.0-10.5 | 0.44-2.44 | 55 | 149.61 |

| φ2500×50000 | 2.5 | 50 | 3 | 6.25-7.4 | 0.62-1.86 | 55 | 187.37 |

| φ2500×54000 | 2.5 | 54 | 3.5 | 6.9-8.5 | 1.48-1.45 | 55 | 196.29 |

| φ2700×42000 | 2.7 | 42 | 3.5 | 10.0-11.0 | 0.10-1.52 | 55 | 198.5 |

| φ2800×44000 | 2.8 | 44 | 3.5 | 12.5-13.5 | 0.437-2.18 | 55 | 201.58 |

| φ3000×45000 | 3 | 45 | 3.5 | 12.8-14.5 | 0.5-2.47 | 75 | 210.94 |

| φ3000×48000 | 3 | 48 | 3.5 | 25.6-29.3 | 0.6-3.48 | 100 | 237 |

| φ3000×60000 | 3 | 60 | 3.5 | 12.3-14.1 | 0.3-2 | 100 | 310 |

| φ3200×50000 | 3.2 | 50 | 4 | 40.5-42 | 0.6-3 | 125 | 278 |

Case related engineering