- Home

-

Product

- Industrial Grinding Machine

- Vertical Roller Mill

- Raymond Mill

- YGM Grinding Mill

- MTW European Trapezium Mill

- HGM Grinding Mill

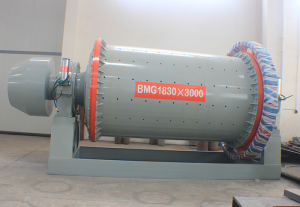

- Ball Mill

- Raymond Mill

- Industrial Drying Machine

- Rotary Dryer

- Three Drum Dryer

- Poultry Manure Dryer

- Sand Dryer Machine

- Fly Ash Dryer

- Wooden Sawdust Dryer

- Three Drum Dryer

- Calcining Kiln Machine

- Hydrated Lime Plant

- Lime Rotary Kiln

- Lime Shaft Kiln

- Cement Rotary Kiln

- Metallurgy Rotary Kiln

- Bauxite Rotary Kiln

- Lime Rotary Kiln

-

Solution

-

Video

-

Case

-

About Us

-

Contact